UPDATE

Since posting this blog and chatting on Instagram Front Runner SA commented why I’m making a mistake adding the rubber trim.

Here’s what they said:

Using any type of rubber on the legs will not allow a firm and solid clamping force and will allow too much movement. The movement can cause damage to the gutters and can eventually lead to failure of the mounting system. If you’d like to chat further please dm your contact details and one of our product consultants will be in touch.

Regards, Team Front Runner

I then asked what I can do about any damage to the paint from metal on metal?

Thanks for the info. What do you recommend to avoid the paint coming off the gutter?

@geordiejimny

Here’s what they said:

If there is no movement and the clamps are secured correctly you should not have any paint coming off. The clamping surface area is quite big. If the clamping surface was small the force would be more concentrated and could cause damage. If you want to chat further please share your contact information and we will be in touch.

Regards, Team Front Runner

I also got an interesting message from Anders Hybel-Brauner that mentioned:

I had the same worries about the roof rack from Front Runner and decided to mount as instructed. My friend who is a stunt safety expert recommended NOT to mount with rubber due to the massive torsion. The rubber cant be tightened enough and will give in to the torsion when the car moves especially offroad.

Anders Hybel-Brauner

There were far more people messaging to say that they do add rubber trim or other paint protection to their front runner rack but I best follow the advice from Front Runner and remove it. Carrying a roof tent on the Jimny is taking enough risks as it is without adding to them. I will post an update here if any paint damage does occur but given the result from a quick poll it seems like we should be ok. Granted, it’s only 28 people who said they don’t use it from that poll but I’ve not seen any posts of people complaining.

Original Blog Article

A common worry for folks using Front Runner racks or load bars mounted into their rain gutters is the metal feet potentially damaging the paint. This issue happened to me and I’d used thin paint protection film that clearly wasn’t up to the job.

By now I imagine most gen 4 Jimmy owners will have noticed the paint is soft and scratches easily. Along with surface rust appearing on many parts of the cars underworld. Metal on metal can’t be ideal and I am not certain why the gutter mounted feet and outer brackets do not come standard with rubber covers. My cheap Thule ones had them. I’m sure there’s an explanation beyond simple cost saving on Front Runners behalf and I’m not writing this blog to bash them.

The load bars I use are great and I’ve learnt that it’s my responsibility to maintain them to keep them in good working order. Something I was guilty of not doing in the first 12 months of fitting them on the Jimmy. Living in a North East coastal location in the UK I should know better, all that sea air and relentless rain is going to take its toll on any kit I use. Thankfully, Front Runner replaced the parts that suffered the worst of the powder coating flaking and rust, hence how I discovered the damage to the paintwork in the rain gutter.

The first thing to sort was a more reliable barrier between the feet and the rain gutters to avoid any paint damage. As always I asked you lovely lot on Instagram what you use and got dozens of ideas back. The most popular suggestions were:

- Cut strips off old inner tubes

- Use Helicopter tape

- Use rubber edge trim

- Stop being a pussy

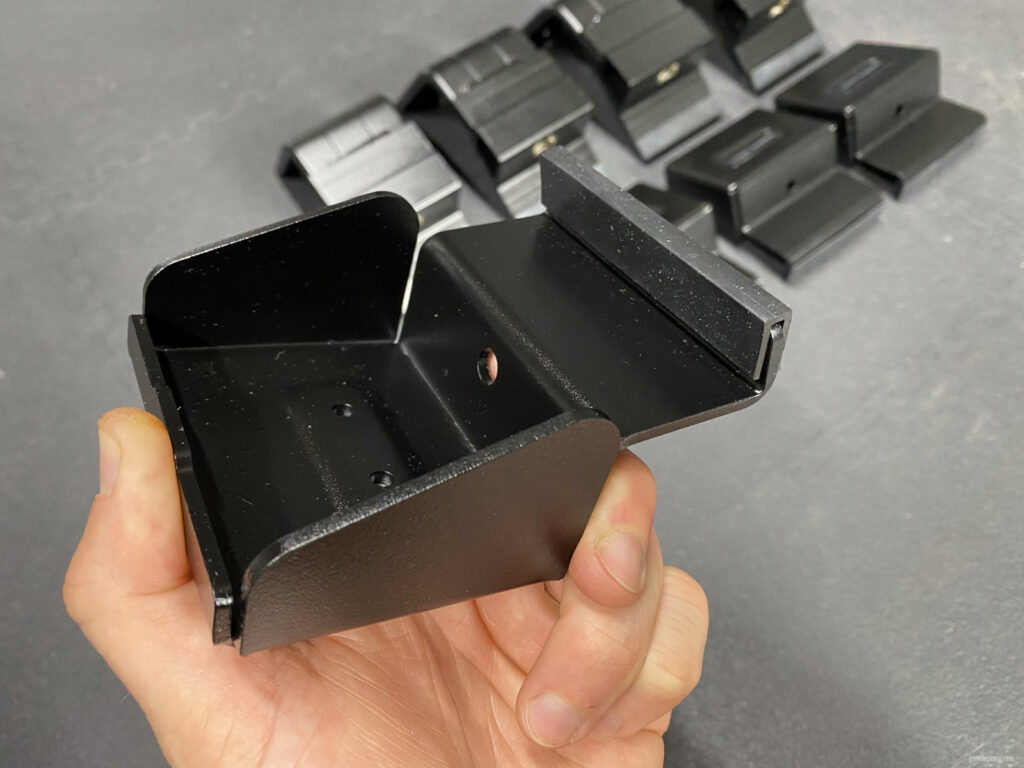

I chose to hunt down some rubber edge trim on eBay. I can’t believe I’d forgot about the Shower U Channel rubber trim I used on the backing panel of the first tailgate molle panel I made. That stuff would be ideal in a larger size. As luck would have it, it does indeed come in larger sizes. Specifically:

- Feet – 15mm x 4.5mm (5mm depth would be better if you can find any)

- Outer Bracket – 15mm x 3mm

It comes in strips that you can simply cut to size. I bought the shortest length they had, 1m for each each size.

Here’s how it looks fitted.

If you can find 5mm depth U channel trim that would be an even better fit.

I repaired the paint damage to the rain gutter and fixed some corrosion issues on the load bars where I drilled through to mount to tent directly onto the bars. I believe it was the washer rusting against the wind deflector that in turn cased some damage to the slat seen below.

I also decided to treat the entire load bar kit with Lanoguard. The replacement feet, load bar slats and the hardware, as they rusted the most and seemed to be the cause of the corrosion issues on the slats. The wind deflector rusted but there was no rust on the slats or feet. No failures in the kit obviously. To be clear, there’s probably no point rust proofing these as quite a few people who have used this kit longer than I messaged on Instagram to say they were really surprised I had any issues at all.

Lanoguard adds a thin candle like coating to the metal and small particles of dust seem to stick to the load bars.

I’ve not noticed on the parts of the underbody after the treatment I did. Maybe it’s there but impossible to see. Regardless it’s hardly an issue. You can jet wash parts treated with Lanoguard so I think it will lessen over time. I’ll happily take more longevity in the kit with the extra rust prevention. It’s worth a try to see if it helps. I can easily remove the protection with a citrus based cleaner.

Here’s the final view of it all fitted on the Jimny and where I’ve located the main part of the feet to avoid damaging the the rain gutter.

This is obviously basic information that most of you will already know but for those who don’t I hope it has helped. If anything, at least you can use the links or search for something similar.

Cheers!

I have many years experience of working on cars and am a competent mechanic.

I recently fitted some FR bars to my son’s Jimny. They are a solid bar but I was generally underwhelmed by the quality of the hardware and particularly the absence of any protection between the clamps and the paintwork. I have fitted Thule, Yakima and Rhino racks and they all have rubber protection between the paint and the clamps. I too contacted FR to express my concern that there was no protection and they gave me the same line regarding rubber degrading over time and allowing the racks to move. I am not persuaded by this explanation. All the afore mentioned racks are extremely well engineered and they clearly don’t have an issue. I also disagree with the FR comment that the ‘The clamping surface area is quite big.’ My observation is that the clamping service is relatively small and the edges on the mount are sharp. I think that the risk of damage to the paint is inevitable. I also found the instructions extremely poor. I was able to work it out due to the number of similar racks I have fitted but I think many people would struggle. I also note that the instructions do not state the torques values for the mount nuts which is a critical element of the engineering design.

Overall my impression was that they were an attractive looking design but not well engineered and the quality of the fixings was poor.

Hi Paul,

I’ve been sent pictures of many racks from folks on Instagram after posting about this. They all have rubber trim on the mounting feet/brackets. Not certain why FR chose to go a different route with their design.

I was looking for the torque settings too, that is a big oversight.

Strength and weight wise they’re perfect for the roof tent. Good kit, but best option? I couldn’t say having only had Thule square bars that weren’t strong enough but had mounting feet with rubber protection on.

It’s a tricky one as here in the U.K. your options are limited when it comes to high strength load bars that are gutter mounted. At least I’ve struggled to find any!

My friend who’s an engineer was puzzled why there’s no welds on the top sides of the outer brackets too.

It is not just the UK where you are limited to good options…. It seems a lot of the ‘Jimny Retailers’ are just sourcing product and designs ex China and the engineering and design is often poor. I am looking at reengineering some underbody protection guards for a local retailer here in New Zealand and the quality and fit of Chinese samples I’m using for reference is pretty poor. They seem to be the same product as offered by quite a few of the Jimny Retailers… The good news is that with a bit of thought and a few prototypes we will be able to put together something that is well thought though, will fit better, work better and look better too 🙂

Sounds like fun. Share any links when you can mate ????

Hi did you get any details on torque settings for the M8x25HexBolt. For legs

And gutter clamps M8 x 30 Button Head Bolt

I would have thought with such an important item would have been supplied by FC .. always appreciate your knowledge and thanks for posts

Hi Jeffery, cheers mate glad the blog help a bit.

I’ve not been given any info on torque settings unfortunately. Like you, I would prefer to have them!

Hi this is from front runner hope it helps

Hi Jeff,

Thank you for getting back to us.

I had asked the engineering and technical team and the torque range for the feet are the below:

8NM TO 15NM

Regards,

The Front Runner Team

Jeff Lamotte

Jul 10, 2021, 3:40 GMT+2

hi I sent a message a few days ago asking about my slimline rack . I’m currently installing it and need torque settings for the bolts for the feet and gutter clamp

M8x25HexBolt. For legs

gutter clamps M8 x 30 Button Head Bolt

Can you advise please

Regards jeff

Cheers Jeff that’s a big help buddy ????

Looks like Front Runners have given up and now now includes a pinch weld set in every roof rack kit. But there are only 6 pieces, and I can’t figure out if they are for the top or the bottom of the leg.

Hi Egor, yeah I did hear about these. Unsure myself where they go but I suspect the bottoms of the feet that sit in the gutter rail rather than the outside clamped on bracket.

Hi guys, I’ve just recently fitted a new front runner kit to my brand new jimny. I am not happy what so ever. Completely ruined my not even day old jimny paint and the instructions are poor. The six peace pinch weld set can only go on the bottom it seems and not the top as tried both ways yet the rack just moved. With them in the bottom it is every solid but the doors struggle to get past the rubber when opening and closing. More then happy to add photos but it will be off my brand new jimny with scratched paint and a roof rack I wish I never brought.

Hi mate, they come with rubber pinch weld on the racks now? I didn’t get any with my rack or load bars when I bought mine.

Sorry to hear it’s scratched the paintwork!

Just got my jimny roof bars from front runner and yes they come with rubber pinch welds.

No instructions where to fit (online or paper), they do fit on the bit that sits in rain gutter that’s where I’ve fitted first bar (no issue). Used some clear tape on the hook over part to protect paint.

All 3 of my bars have small dent in so waiting for front runner response as can’t carry on fitting others.

I received my Jimmy bars this week, and they now provide rubber 😄. thx to you

😀