While waiting for the parts to arrive to start building the DIY roof tent I thought I’d design a simple fridge slide using Aluminium Extrusion. To get some experience working with it.

The concept was to only use ready made parts bought online with very little DIY, so anyone can do it. I’ll list the parts with links and explain how I made it.

Design

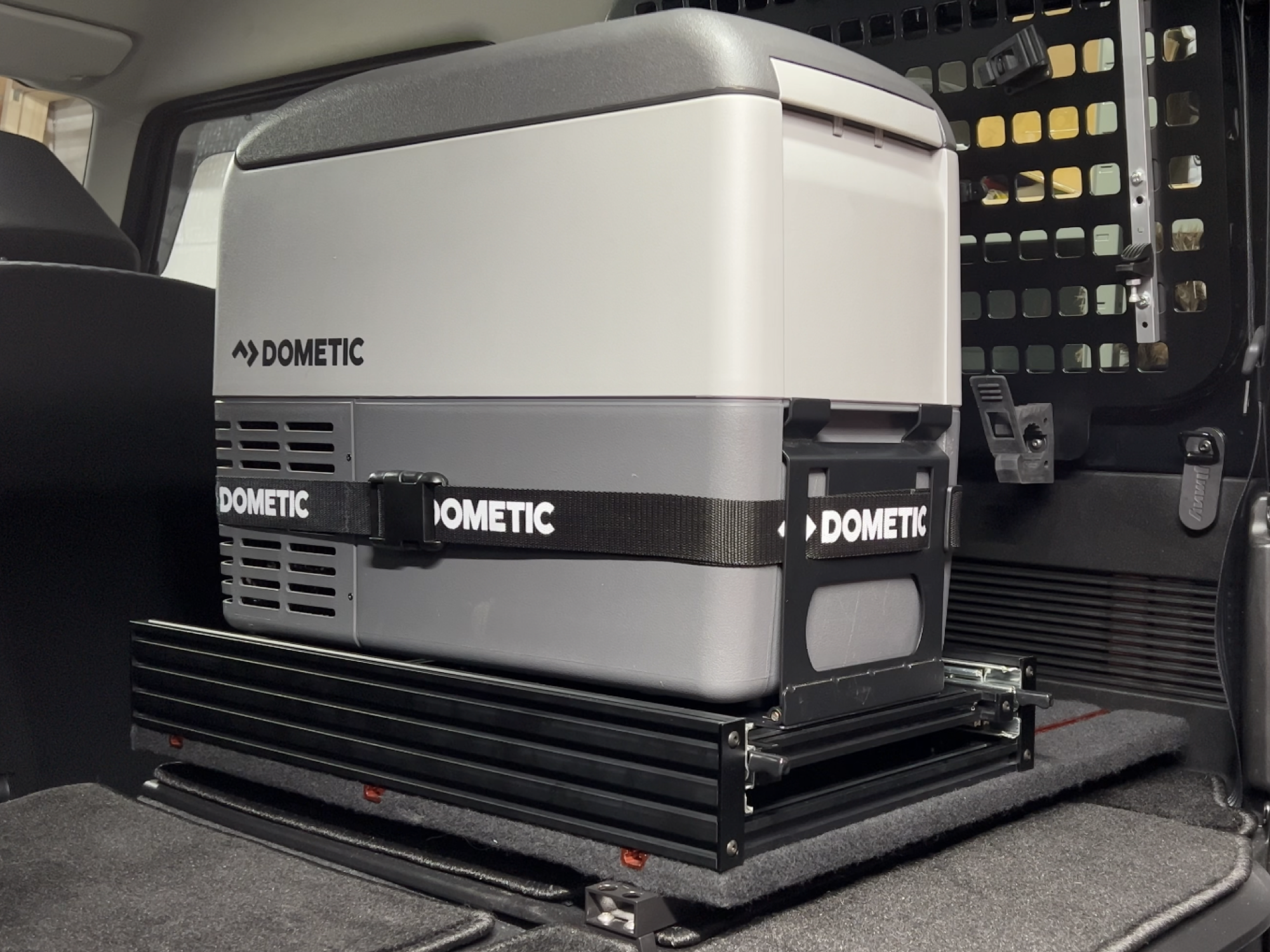

The design is simple, a basic frame to attach heavy duty drawer runners and a platform to secure the fridge mounting brackets too. You’ll obviously need to adapt the design and sizing to match your fridge or whatever size you want the slider to be.

I wanted the slider to be fairly lightweight, clean looking and most importantly to match the size of my fridge.

The reason for this is I own a small 21 litre fridge and if I were to buy a fridge slide it would consume a lot more boot space than I would like. We all know space comes at a premium in a Jimny, as does its payload so a DIY solution makes sense.

This design is a basic frame and slider. On the sliding part I’ve removed the need of a wooden or metal base to save some weight. Aluminium extrusion also allows for eyebolts to be bolted on for an extra ratchet strap to help secure the fridge during transit. The universal fridge mounting brackets that are sold by DOMETIC are surprisingly study but I wanted more security with the Jimny cargo area being wide open and very close to passengers.

I measured the length and width of the fridge including its mounting brackets and added some extra wiggle room. This is where aluminium extrusion comes into its own as using the t-slot system I can move things into the position without needing to drill permanent holes.

Subscribe

Get our monthly email, Out There Life for latest interviews, blogs, camp stories, gear tips & guides, new products and more… straight to your inbox.

Register freeNote, on the base frame that the centre beam is positioned slightly forward so I have enough space to attach the slider to the t-tracks of my boot base.

The width of sliding part holding the fridge needed to be 270mm. The fixed boot platform I’ll be bolting the fridge slider to is a prototype from JimnyStyle. It has a depth of 600mm allowing room for 600mm drawer runners. Longer drawer runners means the fridge will pull further out. You may also want to match the length of the frame to the depth of your boot base.

In hindsight it would have been easier to cut some wood for the slider base as getting the aluminium extrusion to sit perfectly in the right place for the DOMETIC Fridge bracket was difficult.

The modular nature of aluminium extrusion means you can adapt the design to match your needs. For example, you might want to box your fridge in (make sure there’s ventilation), create a side wall to mount other gear or add pull out/drop down tables. I may do this later myself but the first step is a reliable and slick looking fridge slide.

I’ve opted for all parts to ready to assemble out of the box. The aluminium extrusions are cut to size and fixed together using t-nuts and angle brackets. There’s very little DIY work you need to do other than put all of the pieces together, it’s much like meccano.

Parts, links and prices

| Parts | Price |

|---|---|

| 2 x Side Frames 20/80 Aluminium Extrusion, Black Anodised, 594mm (Both Ends Tapped) | £32.10 |

| 2 x Front & Rear Frames 20/20 Aluminium Extrusion, Black Anodised, 308mm | £5.44 |

| 4 x End Caps 20/80 End Caps | £9.60 |

| 2 x Fridge Bracket Supports 20/80 Aluminium Extrusion, Black Anodised, 243mm (Both Ends Tapped) | £14.41 |

| 2 x Slider Side Frames 20/20 Aluminium Extrusion, Black Anodised, 594mm (Both Ends Tapped) | £10.98 |

| 1 x Pair of Drawer Runners Heavy Duty Drawer Runners, 600mm with Lock | £40.88 |

| 4 x Black Aluminium Brackets Corner Bracket, T Nuts and M5 Hex Bolts | £8.59 |

| 20 x Bolts – Pack M5 x 8mm Countersunk Bolts | £5.79 |

| TOTAL COST | £127.79 |

The fridge and mount I have are old models, there are better options now from Dometic and ARB etc. However, if you want the exact same setup here’s the links.

| 1 x Fridge Mount – DOMETIC CoolFreeze CF-CDF-FK Vehicle Fixing Kit | £43.18 |

| 1 x Compressor Fridge – DOMETIC CoolFreeze CDF 26, 21 Litre | £368.47 |

Assembling the parts

As long as you have planned your sizing correctly and ordered the right parts you should find this very easy assemble with an allen wrench. It took me 30 minutes to piece it together.

Subscribe

Get our monthly email, Out There Life for latest interviews, blogs, camp stories, gear tips & guides, new products and more… straight to your inbox.

Register freeThe frame

Using corner brackets fix all three centre frames to the side frames and carefully tighten the bolts on a flat surface, making sure the frame is perfectly square.

I positioned the front and rear 20/20 extrusions of the frame 3mm out from sitting flush with the frame sides. This is so that the 3mm deep end caps would sit flush with the front and rear frames.

IMPORTANT: Drawer runners need to be 60mm wide or less, you will notice when shopping for these that many are 72mm wide which is too big to mount within the space of the 80/20 side frames. Also note that you will need to change the width of your slider base depending upon the depth of your drawer runners. I’ve seen depth ranging from 12.7mm to 19mm when shopping for mine. The runners on this model are 12.7mm deep.

Slide THREE t-nuts into the 3rd channel up from the bottom on both of the side frames. They’ll be used to fasten the outer part of the drawer runners.

To complete the frame bolt the metal end caps on each corner.

IMPORTANT: Depending upon how you plan to fix the frame to your vehicle will need to slide some additional t-nuts into the bottom channels of the frame before bolting on the end caps. I’ve chosen the inner side as it’s neater looking, adding THREE t-nuts to each side frame’s inner bottom channel. I then bolted angle brackets to these and fixed them to the vehicles base board t-tracks.

Slider

Using the M5 countersunk bolts, secure the outer part of the drawer runner to each side of the frame. The countersunk bolts help ensure the drawer runner tracks do not get hung up on the bolt heads.

NOTE: If your drawer runners are shorter than your side frames position the locking levers so that they protrude enough to access them. They’re pressed down to activate.

Instead of how I’ve made mine, I recommend using a piece of wood cut to size for the slide base, then screwing the inner drawer runners to each side. It’ll be far quicker and easier. You can still get a professional finish by gluing car carpet roll onto the wooden base. The aluminium extrusion frame I used on mine was more hassle to make, with little weight savings.

Slide the drawer runners into the frame and you’re done! There’s just the fridge mounting to complete and this will vary depending upon the make and model of your fridge.

Final model viewer

Here’s the 3D model to get a closer look.

Final thoughts

This was a fairly quick and fun project.

It’s more expensive than using angle brackets and a wooden base covered in carpet. However, I think this gives a more professional finish, almost like a real product.

A professionally made fridge slider from your favourite overland supplier is naturally going to be very nicely manufactured. The biggest problem for me is the size options available and high prices. The sizes usually cater for 40 litre fridges and above and the prices can be around £300-500.

I believe it was worth making a more compact version for the Jimny. It’s lightweight, very sturdy and made to measure.

One downside of aluminium extrusion is the black anodised finish scratches easily. I may raptor coat the frame once it’s looking beaten up. We’ll see how well this works on the roof tent frame I’m working on and revisit it later.

On the plus side, aluminium extrusion is easy to work with, super modular and you can buy it cut to size leaving very little work to do. I’ve done a test ride around town and I’m glad to say there no rattles and I’ll report back here with any updates on durability if I encounter any problems.

Subscribe

Get our monthly email, Out There Life for latest interviews, blogs, camp stories, gear tips & guides, new products and more… straight to your inbox.

Register freeAs always I hope this blog helps. Perhaps you have a better idea for a fridge slider to share, if so please comment below I’d love to learn about it.

Very nicely designed and put together, however I would question the need for a fridge of this size in a Jimny with your stated vehicle use.

Being a Defender traveller/overlander (now Jimny) I have found that on the whole a small coolbox is sufficient when access to shops (1-2 days) is possible, due to the space and weight considerations of a Jimny.

Peter B

It is very impressive! I am curious how the slide is fixed to the Jimny. I am a Jimny-owner from Denmark, and I have the principle that whatever I mount in the Jimny it has to be removable in the case that I have to have passengers etc. (as I also think You mentioned in one of Your early videos)

I have trouble finding the best way to mount something solid and still removeable 🙂

Fair point mate. I have been using the fridge for quite some time and I’ll never go back to a cooler. They’re super efficient and keep food properly refrigerated. The slide I’ve used a few times and it’s just for access convenience and I’ve yet to add a little slide out table to this too. The combination of them together is again just convenience. I camped many times times without either of these items and it’s still fine. I prefer this set up myself but if you don’t need it it’s silly adding it ☺️????

The boot has a modular mounting platform that’s a prototype I’ve been helping to test. Available soon I hope.

Are you taking orders? I’d like to place an order if you’re willing to build it.

Hi Cedric, thanks but no plans to make these for sale. Honestly mate it’s quite an easy project and you can use the plan to get something made the the exact side you need.

I’ve seen some commercially made ones and they’re undoubtedly better than this diy version. However for the smaller fridges this worked better for me.

I’ll be modifying it for the new boot build once this diy tent I’m working on finally gets finished. ????

So happy I found this on a search – looking for something to hold my leisure battery and electrical components – which would be standing up on a board.

Would would you suggest if I used this system – for battery it’s great but for the fuse boxes etc (currently on a piece of ply) – I need that to stand up and be supported ?

It’s extremely strong but I’m sure a piece of ply would be cheaper and just as effective. This was more of a lego style build for people that don’t want much DIY work other than assembly once you have ordered the parts. 🙂